Steam Boilers

At CALDERAS MARKOWICZ S.A., we are committed to providing you with industrial solutions that increase your productivity, optimize your processes and give you peace of mind. Our steam generators, designed with advanced technology, offer humotubular boilers with three effective gas passages, wet bottom, high heat transfer coefficients and high thermal efficiency.

Our steam generators are ideal for industrial steam generation, guaranteeing energy efficiency and a significant improvement in the productivity of your plant.

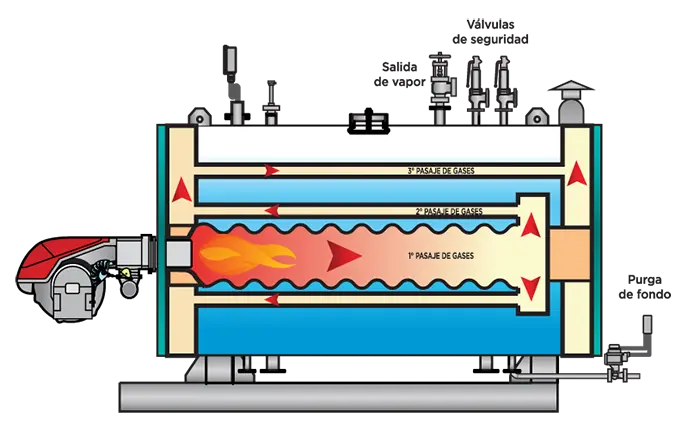

The circulation process starts from the burner, where the furnace acts as the first effective passage of gases. Upon reaching the end of the furnace, the gases are directed towards the first tube bundle, representing the second effective passage. Then, the gases advance and collide with the front door of the boiler, heading towards the second tube bundle or third effective pass, until they are evacuated through the chimney to the atmosphere.

The accessibility to the tubes facilitates maintenance and reduces costs, providing peace of mind to our customers. The inversion of the flue gas chamber, coaxial with the firebox, ensures an optimal distribution of the mechanical expansions, contributing to the long life of the pressure vessel.

Our design reduces radiant heat loss through thick, high-density insulation, as well as front and rear door insulation.

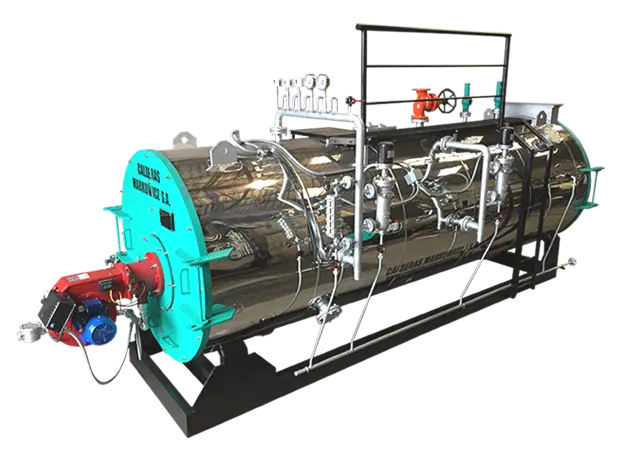

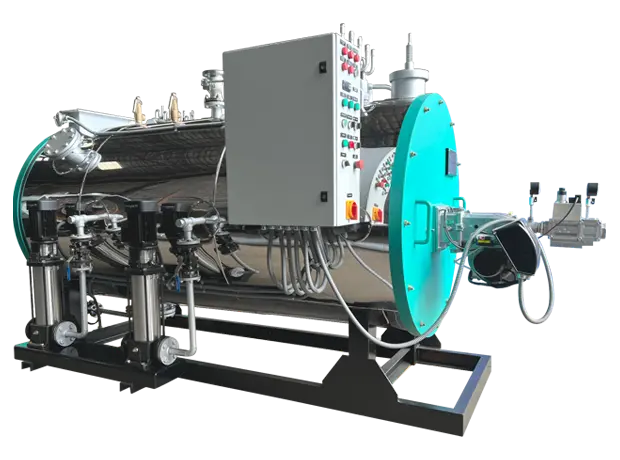

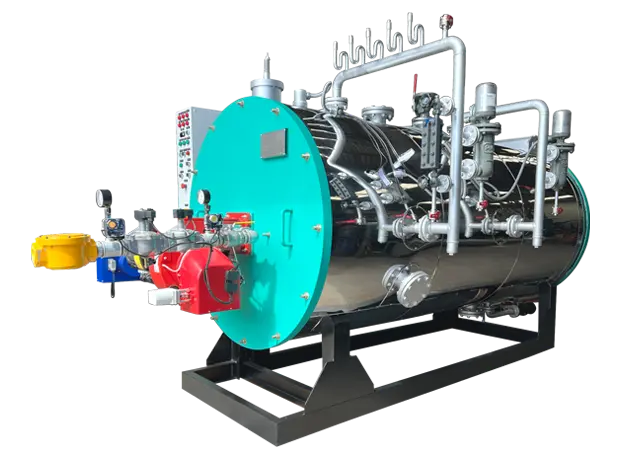

These modern units are delivered mounted on a profile base, which also houses accessory equipment such as water pumps, control stations, oil preheaters, etc. This allows for quick and easy installation, by placing the generator on a simple concrete slab and making the connections for steam, water, natural gas, bottled gas (LPG), diesel or oil, and motive power.

At CALDERAS MARKOWICZ S.A., our promise is to provide you with high-quality products and professional service to support your operations. We are dedicated to providing solutions that not only meet your current needs, but also anticipate and adapt to your future challenges.

Gallery

Specifications

| MODEL | CAPACITY Kg steam/h |

CAPACITY Kcal/hour |

CAPACITY Kw |

Heating surface M2 | OVERALL DIMENSIONS | Approximate weight Kg.(without water) |

Burner Heat Capacity Kcal/hour |

||

|---|---|---|---|---|---|---|---|---|---|

| TOTAL LENGTH | TOTAL WIDTH | TOTAL HEIGHT | |||||||

| LNR 8 | 100 | 66.000 | 77 | 3 | 1.600 | 1.150 | 1.400 | 750 | 100.000 | LNR 15 | 235 | 155.100 | 180 | 5,5 | 2.300 | 1.500 | 1.600 | 1.200 | 178.365 | LNR 25 | 400 | 264.000 | 307 | 10 | 2.800 | 1.700 | 1.800 | 1.900 | 303.600 | LNR 40 | 630 | 415.800 | 484 | 15 | 3.100 | 1.850 | 1.900 | 2.200 | 478.170 | LNR 50 | 800 | 528.000 | 614 | 20 | 3.500 | 2.100 | 2.100 | 2.700 | 607.200 | LNR 60 | 1.000 | 660.000 | 768 | 25 | 3.750 | 2.100 | 2.100 | 3.100 | 759.000 | LNR 80 | 1.200 | 792.000 | 921 | 30 | 3.950 | 2.250 | 2.200 | 3.400 | 910.800 | LNR 100 | 1.600 | 1.056.000 | 1.228 | 40 | 4.750 | 2.500 | 2.600 | 5.500 | 1.214.400 | LNR 125 | 2.000 | 1.320.000 | 1.535 | 50 | 5.800 | 2.500 | 2.600 | 6.600 | 1.518.000 | LNR 200 | 3.140 | 2.072.400 | 2.410 | 80 | 4.850 | 3.100 | 3.500 | 10.800 | 2.383.260 | LNR 260 | 4.000 | 2.640.000 | 3.070 | 100 | 5.900 | 3.100 | 3.500 | 12.700 | 3.036.000 | LNR 320 | 5.000 | 3.300.000 | 3.838 | 125 | 7.200 | 3.100 | 3.500 | 14.600 | 3.795.000 | LNR 640 | 10.000 | 6.600.000 | 7.676 | 250 | 8.900 | 3.950 | 4.350 | 24.500 | 7.590.000 |